Chemical & Material

Security Ink: Compliance and High-Feature Density Drive the Market Toward Nearly USD 5.5 Billion by 2032

07 February 2026

February 8, 2026—According to APO Research’s latest 2026 update, the global security ink market generated about US$ 4.0 billion in 2025 and is expected to reach around US$ 4.2 billion in 2026. Supported by multi-year refresh cycles in banknotes, official documents, and brand-protection programs—together with rising feature density as counterfeit pressure evolves—the market is expected to approach about US$ 5.5 billion by 2032, implying a 2026–2032 CAGR of roughly 4.8%. The category’s growth is structurally policy- and risk-driven rather than cyclical: the cost of a security failure is asymmetrically high, and once an ink is specified and qualified, customers rarely “trade down” on performance in real terms even when broader end-markets soften.

Security ink is a class of purpose-designed printing inks and functional coatings used to embed authentication, anti-counterfeiting, tamper evidence, and traceability into printed features on documents, packaging, and labels, where the “specification” is the verification behavior (what changes or can be read, under what condition, with what discrimination margin) rather than conventional color reproduction alone. In practice, security inks are engineered to deliver overt features visible to the naked eye, covert features readable with simple tools or defined illumination bands, and forensic-level markers intended for controlled laboratory or instrument verification, and they are selected as part of a broader security architecture that also includes substrate choice, print process constraints, inspection workflow, and supply-chain control.

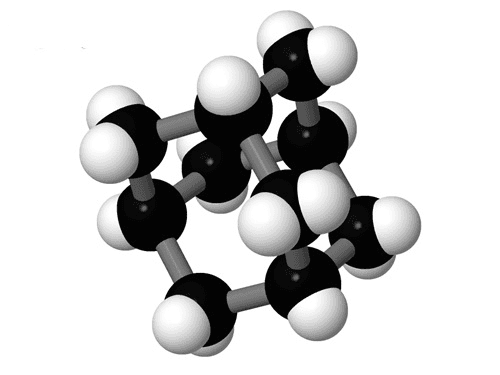

Material-wise, security inks are structured formulations built around a binder system (nitrocellulose, acrylics, polyurethanes, polyamides, vinyls, or UV-curable oligomers), solvent or reactive diluent, and colorants, then differentiated by “effect” components that create hard-to-copy signals: optically variable pigments (interference and color-shift flakes, liquid-crystal pigments), fluorescent and phosphorescent dyes or phosphors (UV and sometimes IR-responsive), magnetic pigments (typically iron-oxide families) for machine sensing, IR-absorbing or IR-transparent components for camera-based sorting, and low-dose taggants (rare-earth–doped particles, microencapsulated markers, or other proprietary tracers) for forensic confirmation. The process constraint is inseparable from the chemistry: the same effect material behaves differently under intaglio, gravure, offset, flexo, screen, inkjet, or UV-inkjet because film thickness, pigment orientation, dot gain, curing profile, and registration accuracy determine whether the security response is stable and discriminable; many deployments therefore use layered constructs (for example, a covert layer protected by an overprint varnish, or an overt optically variable element paired with a covert fluorescent channel). Manufacturing is essentially controlled dispersion and contamination management: bead-milling to a defined particle-size distribution, controlled addition of sensitive markers, filtration (especially for fine-line work and inkjet), and QC that measures not only viscosity and adhesion but the actual signal signature (spectral emission or absorption profile, magnetic response, angle-dependent color shift), plus accelerated aging to ensure the feature survives abrasion, folding, light exposure, solvents, and temperature cycling without drifting into false accept or false reject.

In the value chain, upstream is split across several specialized input tiers that are often more critical than generic ink raw materials. One tier is binders and cure chemistry (resins, photoinitiators, reactive diluents, stabilizers) supplied by polymer and specialty-chemical producers. A second tier is “effect materials”: interference-flake and pearlescent pigment makers (mica or synthetic substrates coated with metal oxides), fluorescent dye and phosphor producers (including rare-earth–based phosphors for high-stability emission), magnetic pigment manufacturers (iron-oxide and engineered ferrite grades), and IR-absorber suppliers tuned for camera and sensor bands. A third tier is controlled taggant technology, where materials may be produced in small-volume, high-control programs with chain-of-custody expectations. Midstream, security-ink formulators integrate these inputs into qualified products matched to a printer’s exact process window, and they frequently co-develop with secure substrate providers (banknote paper mills, polymer banknote-film suppliers, security-label face stock and adhesive suppliers) because ink–substrate interaction is part of the security function. Downstream, secure printing works and high-security converters implement the inks under controlled access, then brand owners, central banks, and government agencies define threat models and inspection rules; parallel to that, device and systems vendors supply the verification ecosystem (UV/IR lamps, magnetic readers, machine-vision camera systems, inline inspection on presses, and handheld field authenticators). Value is ultimately captured where the ink feature remains reliably verifiable in real handling conditions while being operationally difficult to source, reproduce, or simulate—meaning security ink is as much a controlled industrial system (qualified materials, restricted distribution, documented change control) as it is a pigment-in-resin product.

On the supply side, expansion remains incremental and disciplined. Global installed capacity reached 4,487 tons in 2025 and is expected to rise to 4,657 tons in 2026; by 2032, capacity is likely to be around 5,670 tons. Output is growing slightly faster than nameplate, with production at 3,725.0 tons in 2025 and expected 3,921.4 tons in 2026, moving toward about 5,200 tons by 2032. This gradual tightening of utilization is consistent with how security-ink plants are operated in practice: restricted formulations, qualification barriers, and compliance overhead make debottlenecking and yield improvement economically preferable to aggressive greenfield build-out, particularly for intaglio and specialty-feature lines.

Regionally, security inks continue to show a clear split between where they are produced and where they are consumed. In 2026, Europe and North America remain the principal production bases (1,646.2 tons and 1,181.1 tons of output, respectively), while China’s demand continues to exceed domestic output (sales of 1,032.1 tons versus production of 418.8 tons), reflecting ongoing reliance on qualified cross-border supply for certain feature sets and legacy print platforms. On the demand side, Europe is expected to deliver about US$ 1.34 billion in 2026 (roughly one-third of global revenue), followed by China at about US$ 1.07 billion and North America at about US$ 0.92 billion; by 2032, these are expected to reach approximately US$ 1.90 billion, US$ 1.42 billion, and US$ 1.22 billion, respectively, with Europe compounding faster as regulated traceability programs deepen and label authentication penetrates higher-mix packaging.

By technology type, value remains anchored by offset inks and intaglio inks, which together account for roughly two-thirds of global revenue. Offset inks delivered US$ 1,387.5 million in 2025 and are expected at US$ 1,500.2 million in 2026, moving toward about US$ 2.0 billion by 2032. Intaglio inks delivered US$ 1,292.2 million in 2025 and are expected at US$ 1,344.7 million in 2026, approaching about US$ 1.78 billion by 2032. Importantly, value growth is increasingly feature-density driven—covert markers, machine readability, and durability upgrades—rather than purely tied to printed area, which keeps the price–value proposition resilient even where volumes are stable.

By application, security labels remain the dominant engine and the clearest structural grower: US$ 2,097.6 million in 2025, expected US$ 2,228.4 million in 2026, and projected to reach about US$ 3.03 billion by 2032. Banknotes remain a steadier and more politically mediated pool (US$ 801.1 million in 2025; expected US$ 828.8 million in 2026; projected about US$ 1.04 billion by 2032): digital payments are a real headwind, but redesign cycles, counterfeit incidents, and the need to extend circulation life sustain spending on durability and security features. Official identity documents and tax banderoles sit between these extremes—volume growth is modest, but specifications tend to “trade up” as verification becomes more machine-assisted and regulators push traceability and enforcement, supporting resilient value growth over time.